How Drinks Get Inside Cans?

Did you ever wonder how your favorite soft drink or energy came to be in those cans that shimmer? It’s interesting. The job is done using a special kind of machine - The can filling machine from U Tech, similar to the U Tech's product like automatic can filling machine. These machines are designed by some of the top engineers and it helps in filling cans quickly at factories.

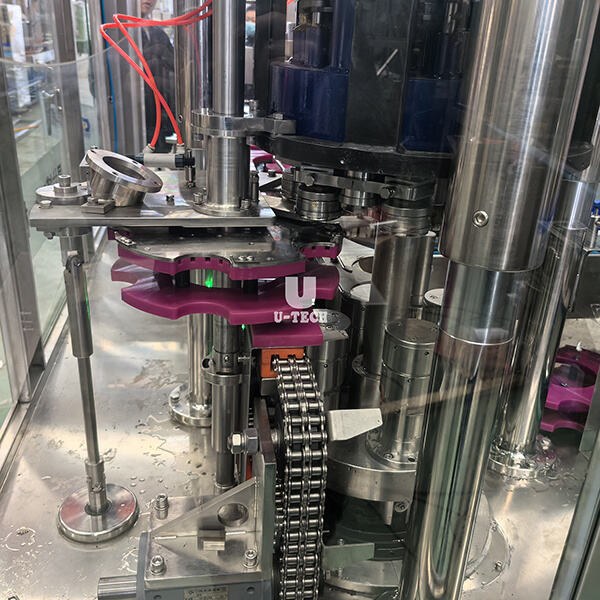

One of the most important and essential pieces, however is that they are essentially working parts which all must come together in order to fill cans with drinks, just like the beer can filling machine by U Tech. To begin with, there is something called a can conveyor. It is just like a conveyor belt that transmits the empty cans from one place to another. It facilitates the conveyer of cans across a production line. Filling station is in our next spot. Here the delicious drinks are going to be filled into cans on this machine. This is important because this is when the cans are filled with beverage. Next comes a mopper. This bit of machinery ensures that the cans are sealed tight so nothing leaks. At last, and the most essential is that we have a controller which will function as parasite to this apparatus. It looks at happening everything, almost like a forensic officer to ensure the whole process goes as expected and without any issues.

A good can filling machine is of extreme importance for anyone that makes drinks, the same as U Tech's soda can filling machine. This will allow you to make a lot of beverages much faster. Many popular can filling machines available today so opt for beer can filling machine from U Tech.

Using technology these days filling machines have become a lot more sophisticated. Today, these machines need less human intervention now and are quite efficient. One of the appealing aspects is that they are engineered to be extremely effective per material use and waste output. These machines are loaded with special sensors that guarantee the appropriate level drinks to be filled up also never making a spill. Clearly important, but also keeps air out of the cans and that can make drinks taste better.

The new filling machines can even monitor production in a way that we could not imagine only a few years ago, similar to the soft drink can filling machine. This allows manufacturers to track ways all their manufacturing is doing real quick. In so doing, they are able to determine as need their attention and develop ways in order be effective. In this way, the tracking becomes essential for assuring that everything goes well at several points in production so opt for liquid filling machine from U Tech.

On your initial go this might seem a tad but is wise as you can save loan, the days and many more when it comes to energy by buying high quality machine may that will packer. These automatic bottle filling machine are very valuable for businesses and all suppliers who offer these machineries, they want to provide top quality at competitive prices. Some of the key benefits to using a trustworthy filling machine include:

Increased Production - A good machine helps the operator to fill cans at a rapidly; this goes on to increase production rates, the same as U Tech's carbonated can filling machine.

Improved Quality Control - These devices are meant to fill volume correctly each time. This automatic liquid filling machine ensures that all the cans contain an equal amount of drink, and thus customers get what they come for.

Satisfied Customer: Happy Customers - The more quality drinks you offer, the better your brand will be. Which in turn can increase returning buyers, even better.

Great canning machine for sale as well cracked fresh technology is crucial It is what makes your production flow properly so that it keeps high quality standards and thus it gets you closer to the fulfillment of revenue goals. When it comes to your business the price for new equipment can be worth the success you see down the road.

We design and manufacture parts for machines using CNC machine. We are accredited by CE TUV, CE, and ISO9001. From the layout of the plant to manufacturing equipment and production line installation, we offer the best service for our customers. Our products are well-known and trusted by consumers and are able to meet ever-changing requirements in social and economic conditions. Now our products are exported across more than twenty countries and regions which include South America, Middle East, Beverage can filling machine, Russia, the Commonwealth of the Independent States, Western Asia and South Africa.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and packaging firm with a talented technical team and well-equipped testing facilities. We offer liquid filling systems for water, tea, carbonated drinks, alcohol, oil and plant protein drinks.), barreled filling line (: 1-5 gallon) water treatment machines, Beverage can filling machine, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We will deliver the machine at a time, according to the date agreed by Beverage can filling machine. We will give 2 years free spare parts and lifetime support following the time the product is delivered. We will offer free spare parts within 24 hours via international professional express and lifetime technical support, with 24-hour response from engineers. (All services are delivered to customers within five days using Intl courier). Contact us to build friendships that are mutually beneficial to new and existing customers.

With a wide range, good quality, reasonable costs and attractive designs Our products are widely utilized in Beverage can filling machine and other packing equipment. We design bottles, labels as well as factory drawings. We will keep you updated of the timetable for production during the process of production. We will customise the machine to your specific requirements such as material, power and type of filling bottle styles, etc. You can visit the factories of our projects as reference across the globe if you are granted permission by the customers.