We like to drink sweet drinks such as: juice, soda and water. Ever wonder how a lot of those delicious drinks get into bottles or cans? Bottling equipment is a specialist device that makes it possible! It fills various liquids into the bottles and cans to enjoy them anytime we desire.

Correct bottling techniques for drink makers Drinkmakers.dequeue This is a critical step to ensure your beverages are fresh, safe and flavorful when it arrives at stores or customers. Smart bottling machines can help to speed up this process. You will never have to fill the bottles, seal them or hand label. Hence, less effort is required in each construction and more drinks are prepared for the people to buy.

Drinks are ephemeral, and the industry is always growing to cater to wherever people go next. The point is, in order to remain competitive, you need a better production setup. Technologically advanced bottling machines can help you do all of the above, efficiently. Newer machines such those listed above work quicker and with a higher quality than older models so you can make more without compromising taste. They also guarantee that every bottle is filled to the right amount and sealed correctly.

If you want to make a lot of drinks successful at your drink business. And for you to fulfil this dream, the finest bottling machines available can help! You get to enjoy automatic capping, labeling and filling with these machines. In short, you will be able to make your drinks faster and with less human help. The machines are good with loads of work and hence your team can concentrate on other tasksegment This will help you scale your business and sell to more customers who should be paying for drinks!

Each business will be different and have its specific requirements in terms of bottling drinks. Thats why companies of all sizes depend on specialized solutions. You can have a company that makes bottling machines for your firm and you are almost certain to get one with the widest number of features invented by humankind. If you have a smaller shop, you may require to buy the smallest machine they provide. However, if you run a big factory and have lots of bottles to move at once you may need something on the large end. A tailored solution just for you, can drive the results that you desire and make your life easier.

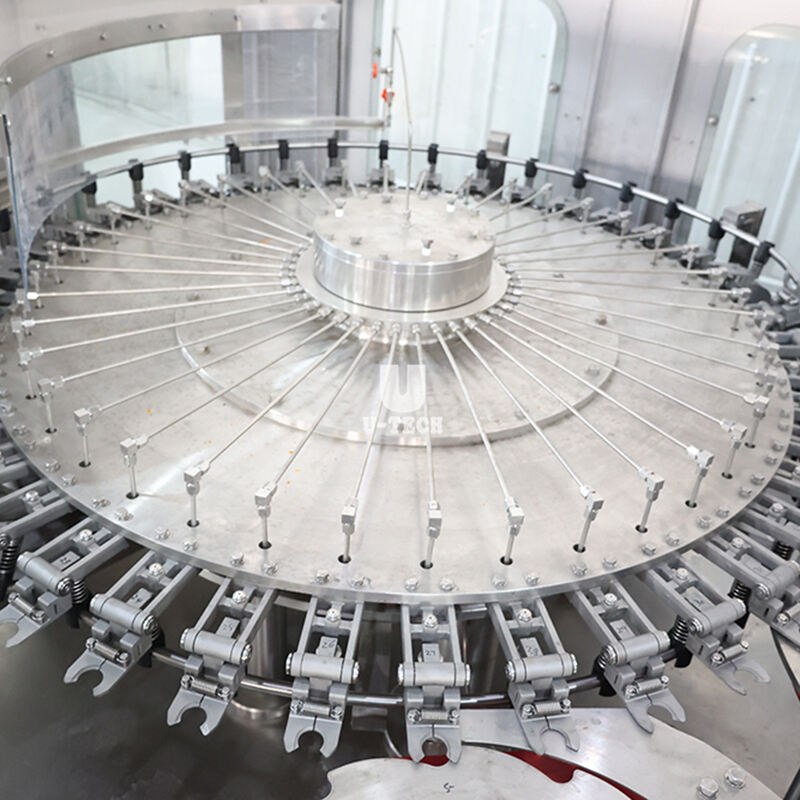

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling machines and packaging company with a seasoned beverage bottling equipment as well as well-equipped test facilities. Our products include: liquid filling equipment (water and fruit juice/tea, carbonated drink, oil alcohol, plant protein drink, etc.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

Our products are extensively used for packaging beverages and other equipment due to their broad selection, quality, affordable prices and attractive designs. We can design bottles, labels or beverage bottling equipment. We will keep you informed of the schedule for production throughout the process of production. We will customize the machine in accordance with your requirements, materials power, filling type and the types of bottles and the like. You can visit the manufacturing facilities of our project references across the world if you have permission from customers.

The machine will be delivered on time to the deadline agreed between both parties. We will offer 2 years free spare parts, and beverage bottling equipment once the product is delivered. We'll provide spare parts in 24 hours via international express professional and all-year technical support with 24 hour engineer response. (All services are delivered to customers within 5 days via Intl courier). We are happy to welcome both old and new customers from all types of industries to reach us for future business relationships and shared success!

beverage bottling equipment create machine parts with a CNC machine. We are certified by CE, TUV, ISO9001 certification. We are able to provide top-quality services for our customers, starting including plant layout production equipment, layout and line design to training for operators and the best after-sales support. Our products are recognized as reliable by the users and are able to adapt to ever-changing economic and social needs. Today, our products are sold to more than twenty countries and regions that include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.