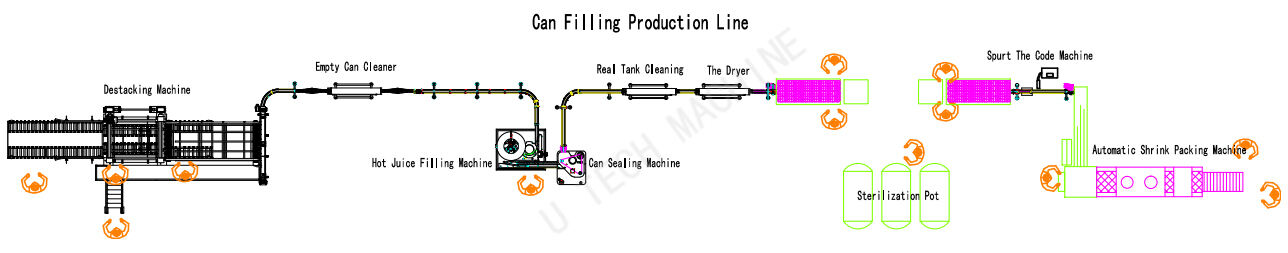

U Tech’s High Technology Small Scale Carbonated Beverage Juice Energy Drink Beer Wine Aluminum Tin Can Filling machine was made to meet with the modern-day requirements of companies and folks in the drink industry. This manufacturing line was made to provide high precision rate, minimizing the requirement for human intervention.

The U Tech’s filling machine line was made to utilize a small-scale carbonated and non-carbonated drink services and products, including juice, energy drinks, alcohol, wine, and much more. The manufacturing line comes with higher rate technology that guarantees the greatest level of precision and accuracy through the whole procedure. Every time using this device, you can be certain your merchandise or services is filled with the best level of liquid.

Among the key features of this manufacturing line is its power to utilize aluminum tin cans in the packaging product. Aluminum cans offer several advantages, including durability, portability, and also the power to keep the beverage fresh for extended periods. The addition of aluminum cans within the U Tech’s filling machine line will ensure your products or services are well-packaged and additionally, aesthetically appealing

The technology used in U Tech’s filling machine production line guarantees quick and efficient operations. The apparatus was made to fill to 50 cans every single minute that makes it ideal for small-scale drink manufacturers with a high manufacturing. The whole process is completely automatic, which eliminates the need for human work, reducing the possibility of individual mistake.

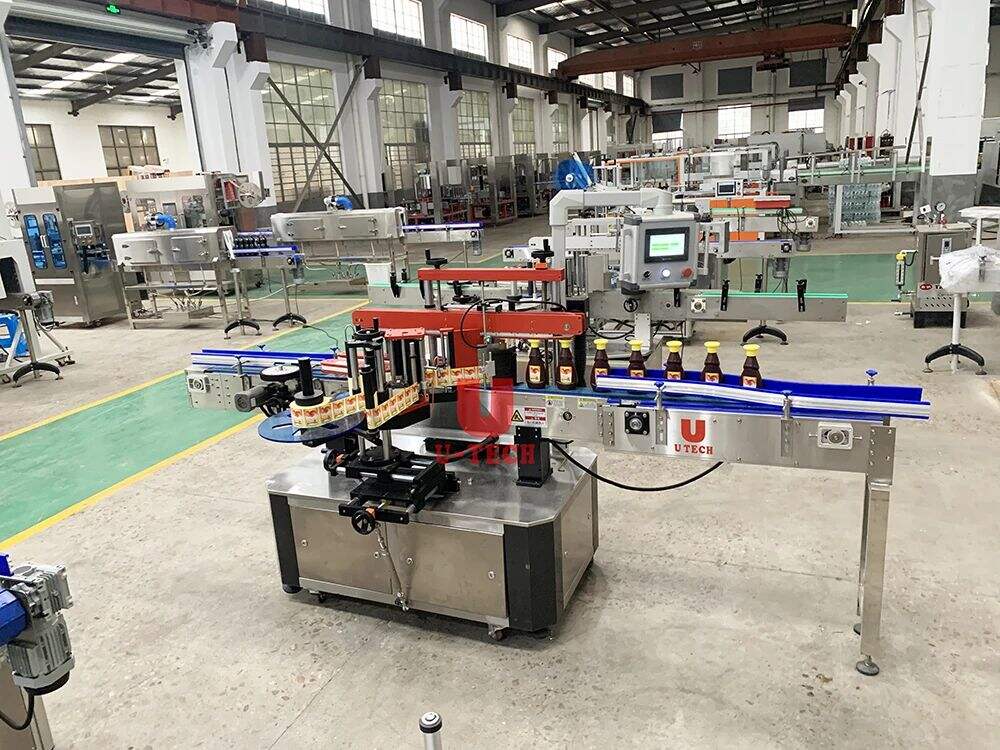

Another good thing about the U Tech’s filling machine line is its simplicity of upkeep. It was produced with quality materials that offer longevity and durability, reducing the necessity for regular repairs. Maintenance is further simplified since the device was created to self-diagnose and adjust whenever necessary.

The U Tech’s filling machine line is safe and effective. The unit has safety features, including crisis end buttons, automatic overload protection, and security interlocks. The intuitive touch control system gives power to operators to generate, run, and monitor the apparatus performance.

U Tech’s High Technology Small Scale Carbonated Beverage Juice Energy Drink Beer Wine Aluminum Tin Can Filling machine is an excellent investment for small-scale drink manufacturers. This device will surely raise the efficiency and profitability of your company, featuring its higher level technology, efficient operations, simplicity of upkeep, and improved security features. Order your U Tech’s filling machine line today, and feel the superior quality it gives

2. Introduction of Wine drink cans filling machine. The machine is composed by the filling and capping parts which produced by abroad introduced advanced technique. The performance and structure both are up to international level. The whole machine joins the mechanical, electric, and pneumatic ways to control

<1>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3>304/316 stainless steel washing

<2>All 304/316 stainless steel construction

<3>No bottle no capping

<4>Automatic stop when lack of bottle

- Air conveyor is fixed on the floor, with fan installed on the top

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power

Model |

BST12-1 |

BST16-4 |

BST24-6 |

BST32-8 |

Capacity |

1200-1500cans/hour |

5000-6000 CPH |

7000-9000 CPH |

10000-12000 CPH |

Can Volume |

200ml-1000ml |

200ml-1000ml |

200ml-1000ml |

200ml-1000ml |

Can diameater |

50-70mm |

50-70mm |

50-70mm |

50-70mm |

Bottle high |

120-170mm |

120-170mm |

120-170mm |

120-170mm |

Machine power |

1.5KW |

2.2KW |

3.7KW |

5.5KW |

Machine size |

175x120x195CM |

305x175x220CM |

340X195X220CM |

350x235x225CM |

item |

value |

|

Condition |

New |

|

Type |

Filling Machine |

|

Machinery Capacity |

10000CPH |

|

Applicable Industries |

Food & Beverage Factory |

|

Showroom Location |

Canada, Turkey, United Kingdom, France, Germany, Viet Nam, Peru, Saudi Arabia, Indonesia, Spain, Thailand, Morocco, South Korea, Algeria, Sri Lanka, South Africa, Nigeria, Uzbekistan, Japan |

|

Application |

Beverage |

|

Packaging Type |

cans |

|

Packaging Material |

Plastic |

|

Automatic Grade |

Automatic |

|

Driven Type |

Electric |

|

Voltage |

220V 380V |

|

Place of Origin |

China |

|

Province |

Jiangsu |

|

Brand Name |

U-TECH MACHINE |

|

Dimension L*W*H |

270x140x190CM |

|

Weight |

3100KG |

|

Warranty |

2 years |

|

Key Selling Points |

Easy to Operate |

|

Filling Material |

gas liquid |

|

Filling Accuracy |

±0.1 |

|

Machinery Test Report |

Provided |

|

Video outgoing-inspection |

Provided |

|

Warranty of core components |

2 years |

|

Core Components |

Motor, Pump, PLC |

|

Type |

Filling Machine |

|

Product name |

Beer Canning Machine |

|

Model |

BST16-4 |

|

Capacity |

170cans/min |

|

Filling speed |

170cans/min |

|

Bottle type |

PET, Aluminium can |

|

Filling material |

Beverage |

|

Control |

PLC+ Touch Screen |

|

Material |

SUS304/316 |

Stainless steel high pressure film shell. All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system. Online type pressure auto self-protection device Online type electricity indicator. System safe protecting and alarm system.

System frame

In the packaging machinery industry, the film wrapping machine is the abbreviation of the wrapping film packaging machine, sometimes called the winding machine and the wrapping machine

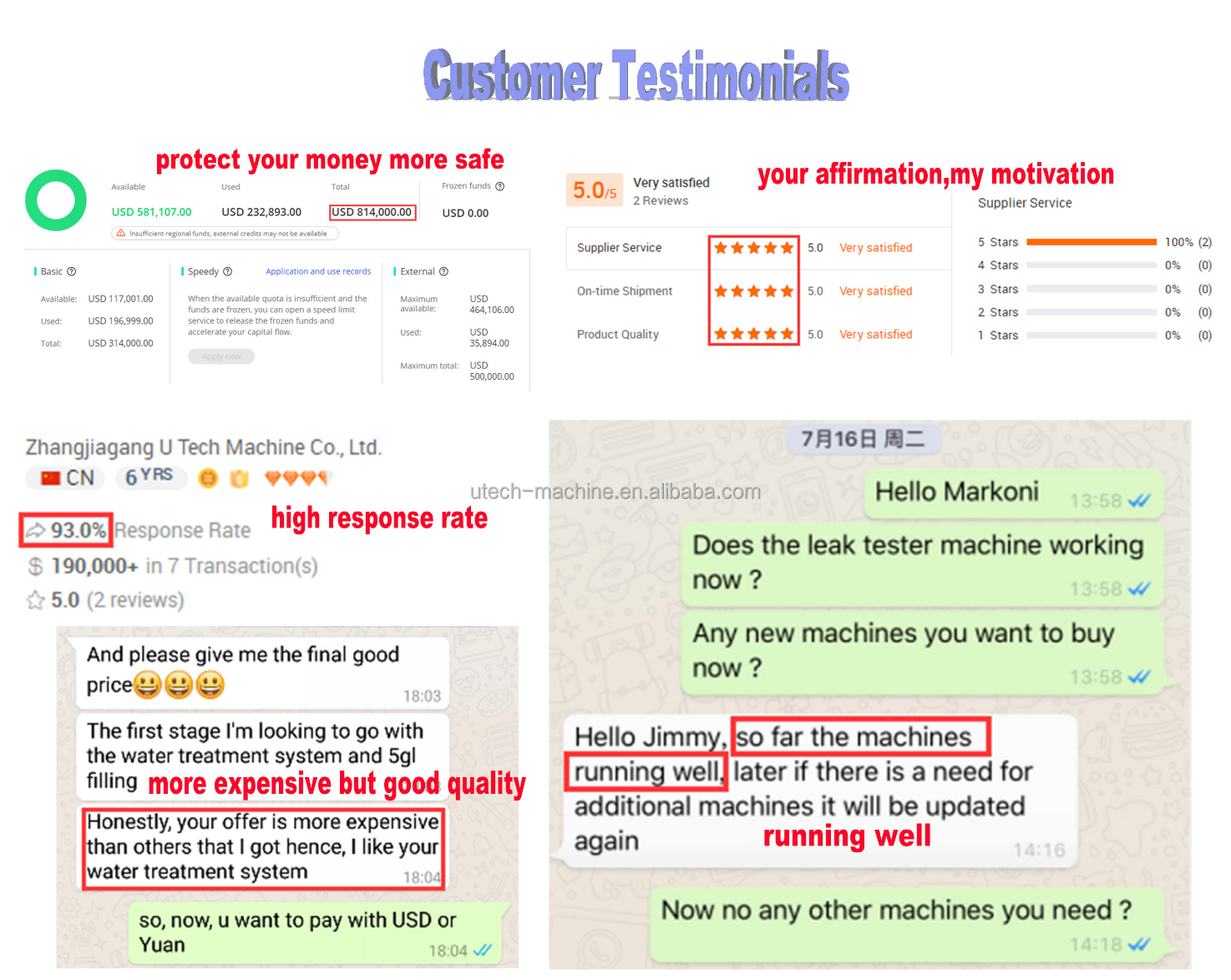

We are based in Jiangsu, China, start from 2014, sell to South America(15.00%), Domestic Market(15.00%), North America(13.00%), Africa(10.00%), Central America(10.00%), Southern Europe(7.00%), Southeast Asia(5.00%), Mid East(5.00%), Western Europe(5.00%), South Asia(5.00%), Eastern Europe(4.00%), Oceania(2.00%), Eastern Asia(2.00%), Northern Europe(2.00%). There are total about 11-50 people in our office