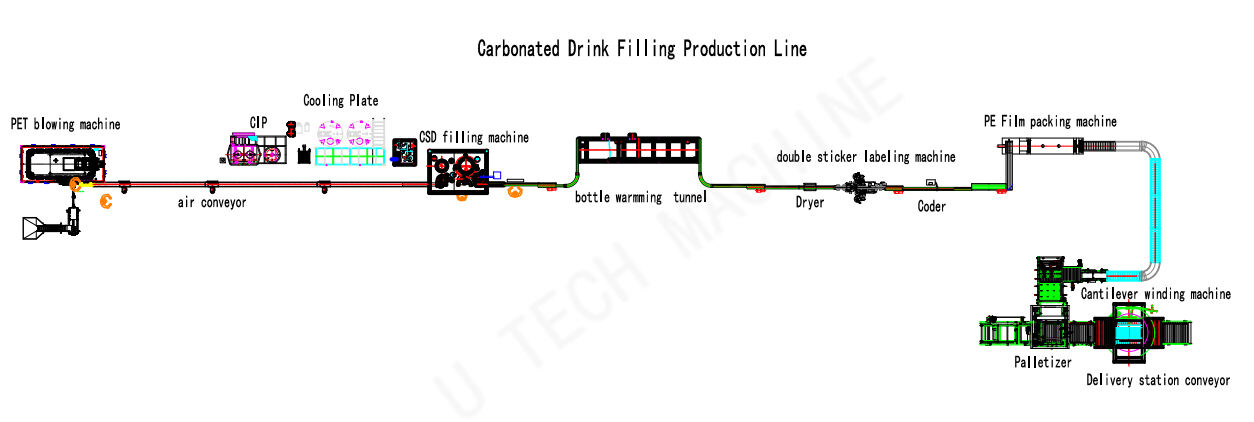

Product introduction

This complete line is used to produce carbonated soft drink, from water treatment to filling and end line packing, capacity is6000 bottles per hour.

Technical parameter

| Model | DCGF8-8-3 | DCGF14-12-5 | DCGF16-16-5 | DCGF24-24-6 | DCGF32-32-8 | DCGF40-40-10 |

| Capacity(500ML) | 1000BPH | 2500BPH | 4000BPH | 6000BPH | 9000BPH | 12000BPH |

| Washing Heads | 8 | 14 | 16 | 24 | 32 | 40 |

| Filling Heads | 8 | 12 | 16 | 24 | 32 | 40 |

| Capping Heads | 3 | 5 | 5 | 6 | 8 | 10 |

| Suitable Bottle | PET Bottle ,Plastic Bottle | |||||

| Diameter of bottle | Diameter: 55-110 MM | |||||

| Height Of Bottle | 150-310MM | |||||

| Suitable Cap | Plastic Screw Cap | |||||

| Weight | 1500kg | 2000kg | 3000kg | 5000kg | 7000kg | 7800kg |

| Main Motor Power | 1.2kw | 1.5kw | 3kw | 3kw | 3kw | 5.5kw |

Machine details

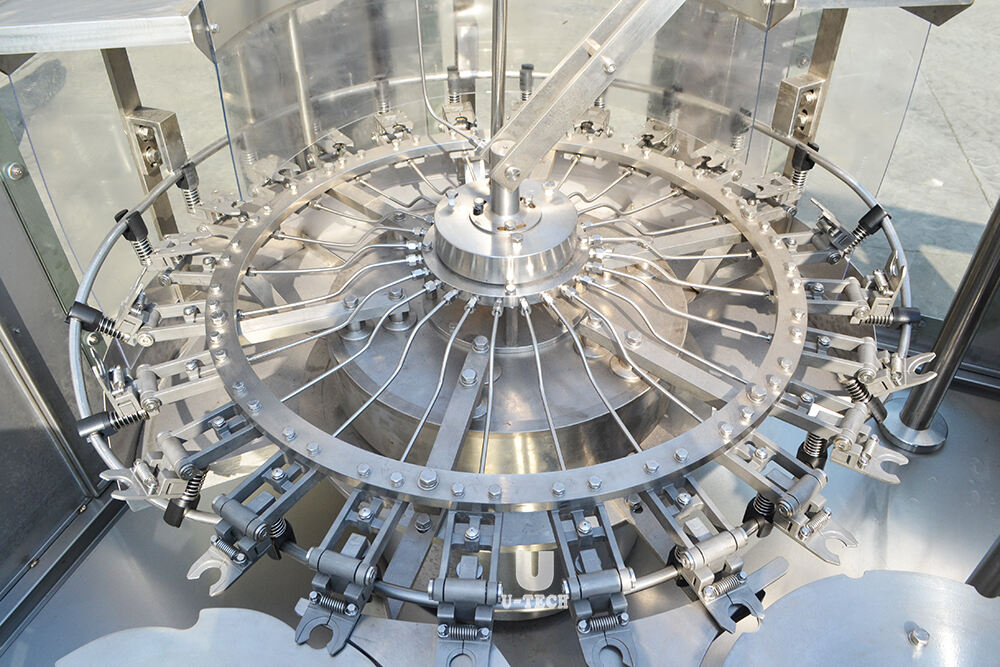

Washing heads

Rotary rinser is one of the key components, which is installed on the clamp, media distributor and other components. When the figure of the rotary bearing rotation, driven turret and the other components are installed on the rotating simultaneously, slewing bearing lubrication in order to concentrate lubrication.

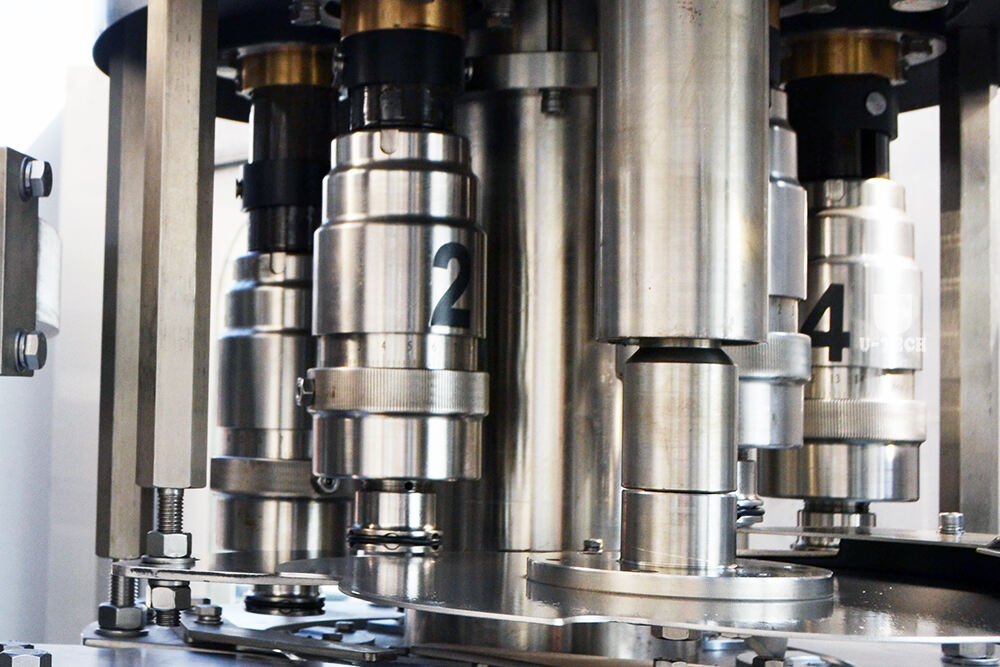

Filling heads

Adopt high precision mechanical filling valves, filling fast, filling accurate and no liquid lose,has features of no bottle, no vacuuming.

Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Capping heads

The capper is made up of hopper, slide way, upper capper, lower capper, rise and fall parts, and preventing turning upright stanchion.

The requirements of crown cap:

Only when the height and diameter all accord with crown cap’s standard, the capper’s normal running can be guaranteed. The crown cap should be stored in the dry room.