U Tech

Establishing the U Tech High-Quality Complete Small Water Bottle Washing Filling Capping Machine Mineral Bottle Water Production Line – an solution ideal seeking the qualified and approach dependable make mineral top-quality it is bottled

This production line has all you need to streamline your production procedure whether or not you might be a continuing business tiny or simply a manufacturer large-scale. Featuring its more range impressive, filling, and technology this can be really capping this implies that each and every container is totally washed, full of fresh mineral water, and tightly sealed – all without the waste or spillage

Here is what you might expect through the U Tech Water Bottle Production Line:

Effective Washing:

The production line comes having a washing advanced which makes utilization of both water and environment to clear each container. It shall create sure that all dirt, debris, and toxins are eradicated, leading someone to be with clean, safe, and healthiest water this will be bottled suits most of the demands which are necessary

Precise Filling:

Making use of high level technology filling the production line indicates that each container is filled with exactly the quantity real is correct of water. You will adjust the quantity specific is filling your desired specifications, making certain you receive outstanding volume of water for every and each container solitary

Tight Capping:

Following the containers are filled, the production line works regarding the system high-speed is screw capping the caps tightly and securely. This prevents any spillage, leakage, or contamination, ensuring your water remains pure and fresh for extended

High-Quality Components:

The U Tech Water Bottle Production Line is manufactured not even close to top-notch elements being developed to last. The item wound up being made insurance coverage companies a framework it is really robust elements being durable ensuring it might probably withstand the rigors of day-to-day use and continue steadily to perform at its perfect for an event very long

The U Tech High-Quality Complete Small Water Bottle Washing Filling Capping Machine Mineral Bottle Water Production Line is clearly a investment great is obviously anyone fantastic to boost their effectiveness and streamline their production procedure. Featuring its advanced technology, efficient performance, and dependable elements, this production line will surely provide the normal best bottled mineral water, quickly and efficiently. Why wait? Have yours you need to your online business to your level today next

CGF Series Bottled Water Filling Machine

CGF series bottled water filling machine line is used to filling mineral water or purified water into PET bottle from 200ml-2000ml. The machine combines washing, filling and capping three functions in a body. The whole process is automatic, filling way using the gravity or micro pressure filling, make the speed faster and more stable

Washing Heads

The advanced card bottleneck technology is adopted to wash the bottle mouth, avoiding the contact with the thread mouth, which makes it more sanitary. The bottle conveying is all adopted the card bottleneck technology, changing the bottle shape without adjusting the height, only changing the protective plate related to the bottle body diameter

Filling Heads

Filling adopts liquid cylinder feeding structure, filling valve adopts new high speed and large flow filling valve, the quantification is accurate

Capping Heads

Screw cap adopts the capping technology introduced from France the cap manager chooses low position installation and horizontal feed cap

item |

value |

Condition |

New |

Type |

Filling Machine |

Machinery Capacity |

18000BPH |

Applicable Industries |

Food & Beverage Factory |

Showroom Location |

Canada, Turkey, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Kenya, Argentina, Chile, South Africa, Kazakhstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia |

Application |

Beverage |

Packaging Type |

Bottles |

Packaging Material |

Plastic |

Automatic Grade |

Automatic |

Driven Type |

Electric |

Voltage |

220V/380V |

Brand Name |

U TECH |

Dimension(L*W*H) |

2200*2100*2200mm |

Weight |

7800KG |

Warranty |

2 years |

Key Selling Points |

Automatic |

Filling Material |

Water |

Filling Accuracy |

99.9% |

Machinery Test Report |

Provided |

Video outgoing-inspection |

Provided |

Warranty of core components |

2 years |

Core Components |

Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine |

Product name |

Bottle Filling Machine |

Function |

Washing Filling Capping |

Capacity |

18000bph |

Material |

SUS304/316 |

Control |

PLC+ Touch Screen |

Filling Liquid |

Water |

Bottle type |

PET Plastic Bottle |

Filling volume |

200ml-2000ml |

Advantage |

Easy Operation High Efficiency |

Model |

CGF |

S/N |

Name |

Brand |

Country |

1 |

Main motor |

ABB |

Switzerland |

2 |

Inverter |

MITSUBISHI |

Japan |

3 |

PLC |

OMRON |

Japan |

4 |

Touch screen |

MITSUBISHI |

Japan |

5 |

Contactor |

SCHNEIDER |

France |

6 |

Thermo-relay |

SCHNEIDER |

France |

7 |

Air-break switch |

SCHNEIDER |

France |

8 |

Proximity switch |

TURCK |

USA |

9 |

Photoelectric switch |

BANNER |

USA |

10 |

Air circuit system |

SMC |

Japan |

11 |

Water pump |

Southern |

China |

Water treatment system

Water treatment system is the process of purifying the raw water by a series of equipment and devices to be drinkable

Blow Moulding Machine

Blow Moulding Machine for PET Bottle is suitable for producing PET plastic containers and bottles in all shapes

Sleeve Labeling Machine

Sleeve Labeling Machine adopts international advanced technology; cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body is designed

Laser Print Machine

Laser printer ejects is a permanent mark that can not be erased. It is formed by the instantaneous vaporization of laser directly on the surface of the object. And no consumables, more convenient maintenance

Automatic Corrugated Case Erector Packer

The upper part of the feed conveyor the product entire column grouping part the lower part of the carton conveying, Lifting mechanism, drop, pneumatic part and electric control part, export products tank transport parts. According to customer requirements for product packaging, the product feed for accurate whole column grouping, while underlying pre-sync to the product carton boxes preset position, and then by the lifting mechanism rear jacking good product grouping randomly fall into cartons, lifting mechanism automatically drops to a horizontal position and the outlet conveyor, cartons output by the transport section

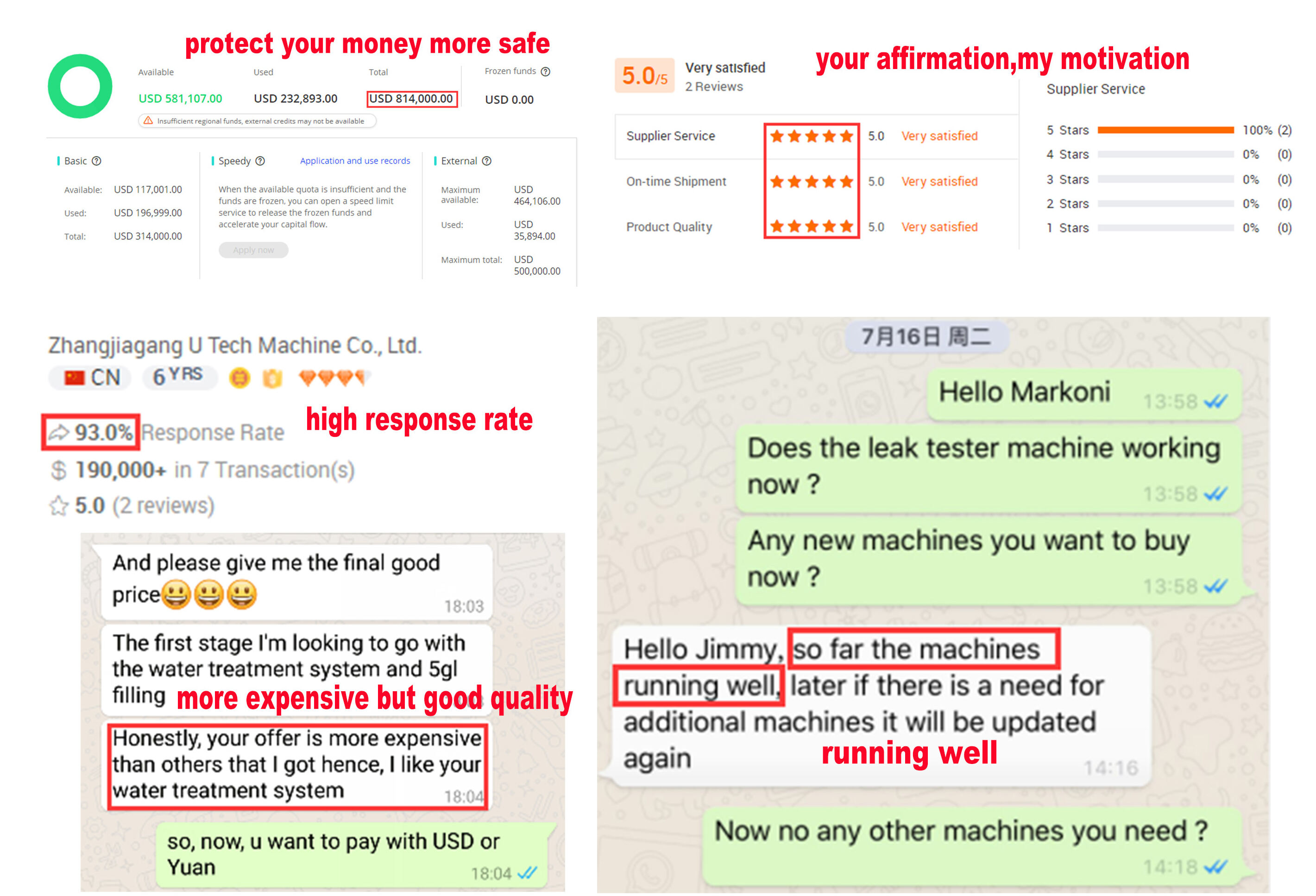

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We can provide best services for customers, from plant layout, equipment manufacture and production line setup to operator training and best after-sales service. All machines are two years' service for all parts, 24 hours for engineer response (all services part 5days in customer hand by Intl' courier). Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success

1. who are we

We are based in Jiangsu, China, start from 2014, sell to South America(15.00%), Domestic Market(15.00%), North America(13.00%), Central America(10.00%), Africa(10.00%), Southern Europe(7.00%), South Asia(5.00%), Western Europe(5.00%), Mid East(5.00%), Southeast Asia(5.00%), Eastern Europe(4.00%), Eastern Asia(2.00%), Oceania(2.00%), Northern Europe(2.00%). There are total about 11-50 people in our office

2. how can we guarantee quality

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us

Water Filling Machine, Juice Filling Machine, Carbonated Drink Filling Machine, Oil Filling Machine, 5 Gallon Filling Machine

4. why should you buy from us not from other suppliers

1.15 years experiences

2. Strict quality control:QC department

3. Reasonable price:factory directly

4. on time service :in 2 hours give u answer

5. 2 years guarantee:you can get any spare part free from us

5. what services can we provide

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency:USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash;

Language Spoken:English, Chinese, Spanish, Arabic