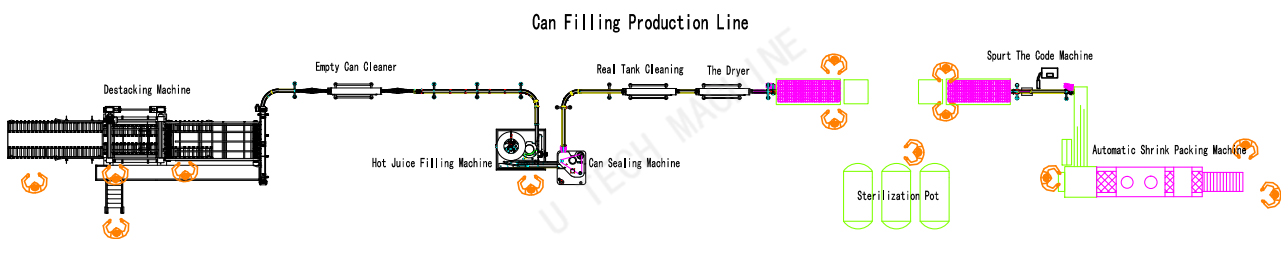

Presenting, this new and improved U Tech’s fully automatic 2021 business aluminum beverage cans filling machines beer bottling line! This system is the perfect solution for small businesses who wants to take their drink manufacturing up to a new level.

The U Tech’s fully automatic filling device was made with all of the latest technology to give maximum effectiveness and accuracy in filling and capping drink cans. The item is indeed easy to use, and will save time and work.

To begin with, this filling machine is wholly automated. This means you do not need any manual intervention to the production procedure. You can easily forget lugging around cans, forget about filling them up one at a time, with no more manual capping. The U Tech’s 2021 model protects almost everything, through the second the cans are filled, capped, and packed.

In addition to the automated function, this product is sold with a top speed filling efficient at replenishing to 120 to 150 cans every single minute! This stuffing ensures that you'll create more cans in a shorter time and enhance your efficiency.

The U Tech’s filling device was created specifically for smaller businesses who wish to upgrade. One of the main purposes in using this is always to save cash since it calls for minimal operator intervention and small upkeep. Its aluminum construction guarantees durability, what this means is you won’t need to change it for a long time.

Another great function of the U Tech’s filling device is that it is suitable for many drink kinds. It can be utilized for alcohol, soft drink, juice, or any beverage that you would like. Plus, having an array of can sizes available, your item range can be personalized to meet up with your customers’ needs.

The U Tech’s fully automatic 2021 business aluminum beverage cans filling machines beer bottling is a top-of-the-line machine that is both affordable and efficient. By purchasing this product, you'll dramatically reduce manual work, enhance manufacturing, save time and money, and improve your business operations. So, why wait? Order your U Tech’s filling device right now and take your drink manufacturing to the next level

Technical parameter :soft drink can filling sealing machine |

||||||||||||

Model |

GDF12-1 |

GDF18-4 |

GDF24-4 |

GDF32-6 |

GDF40-8 |

|||||||

Capacity, cans/hour |

2000 |

8000 |

10000 |

15000 |

20000 |

|||||||

Suitable bottle shapes |

Pop can / Tin can / PET can |

|||||||||||

Bottle diameter mm |

Dia50 ~ Dia99mm |

|||||||||||

Bottle height (mm) |

70-133mm |

|||||||||||

Filling type |

Isobaric filling / Normal pressure filling |

|||||||||||

Application |

soft drink can filling sealing machine |

|||||||||||

Total power (KW) |

2.4kw |

4.5kw |

5.2kw |

6.5kw |

7.2kw |

|||||||

Overall dimensions |

2.5*1.9m |

2.8*1.9m |

3.2*2.2m |

3.4*2.5m |

4.8*2.3m |

|||||||

Height |

2.3m |

2.5m |

2.5m |

2.5m |

2.5m |

|||||||

Weight(kg) |

2000kg |

3500kg |

4500kg |

5000kg |

7000kg |

|||||||

ITEM |

DEVICES |

BRAND |

ORIGINS |

||

1 |

PLC |

SIEMENS |

Germany |

||

2 |

Inverter |

||||

3 |

Touch Screen |

||||

4 |

Switch |

Schneider |

France |

||

5 |

Contactor |

||||

6 |

Relayer |

||||

7 |

Solenoid Valve |

FESTO |

Germany |

||

8 |

Drive Motor |

SEW EURODRIVE |

|||

9 |

Reducer |

SEW EURODRIVE |

|||

10 |

Water Pump |

GRUNDFOS |

Denmark |

||

11 |

Main Bearing |

SKF |

Sweden |

||

12 |

Sensor |

SICK |

Germany |

||

13 |

Air Component |

FESTO |

|||

14 |

Stainless Steel Frame |

POSCO |

Korea |

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee. we will give u spare part free in 2 years

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, material, power, filling type, the kinds of the bottles and so on

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines