U Tech

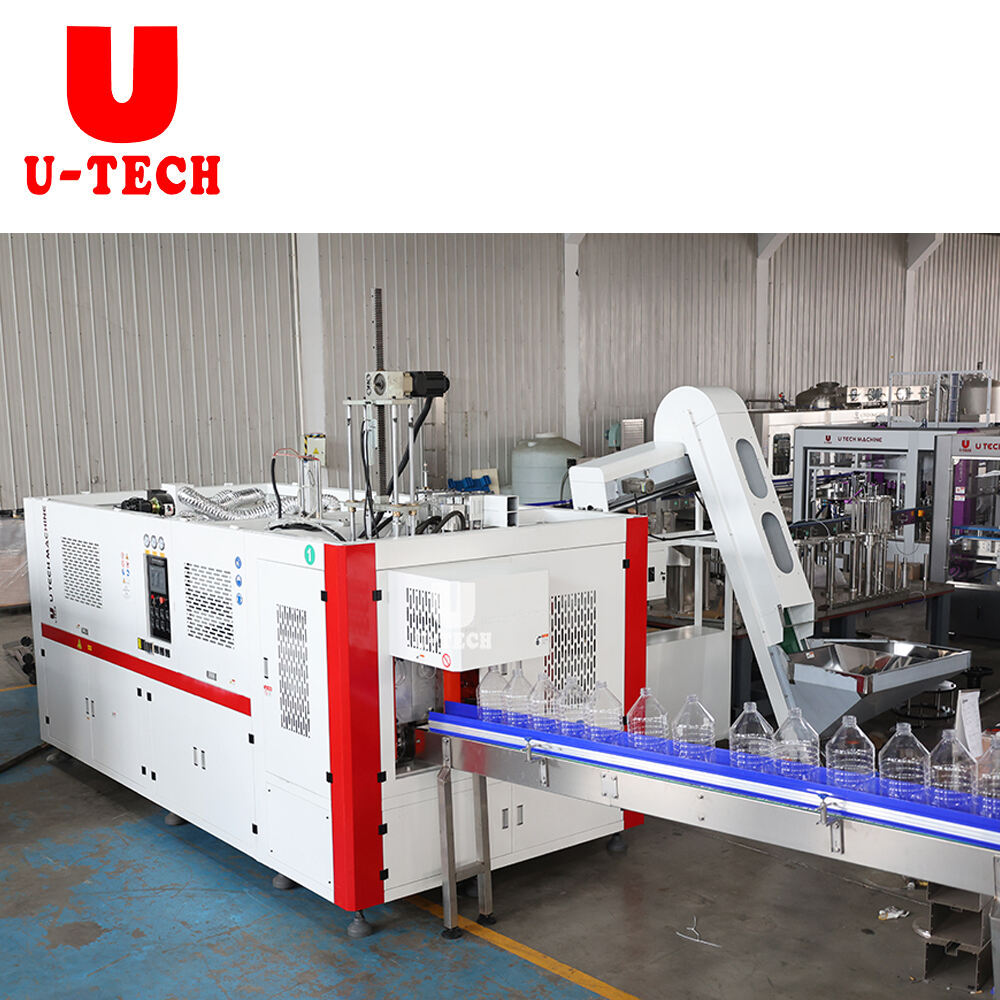

Presenting the entire water tiny Automatic Filling And Capping Pure Drinking Mineral Water Bottling Plant Machine Production Line by U Tech! This user-friendly and machine efficient created to meet the growing interest in bottled normal water both locally and internationally

The U Tech water bottling plant is really a solution comprehensive combines the numerous great things about automatic stuffing and capping to guarantee the degree greatest of persistence and quality. This device is effective at creating ingesting uncontaminated water containers in several sizes to satisfy the diverse requirements of customers

The plant is sold with a design compact making it easy to run and keep maintaining. It offers technology advanced that allow the equipment to work efficiently with a effectiveness high. The installation procedure is easy and fast, enabling organizations to begin out their water bottling operations with just minimal wait

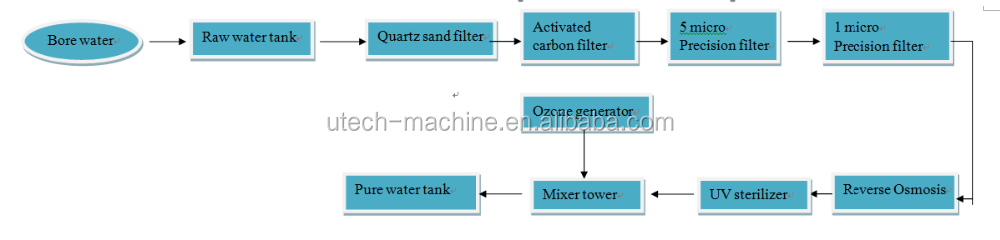

The plant is sold with a top-notch metal stainless therapy system that sterilizes and purifies the water before bottling it. This high level water filtration guarantees the level particular is greatest of hygiene, making water safe for human being usage

Among the list of standout highlights of the U Tech water bottling plant is its capacity to immediately fill containers. These devices efficiently fills the containers because of the purified drinking tap water then seals these with a limit durable means water freshness and purity is preserved. This kind of feature is just a game-changer, because it considerably decreases expenses being functional efficiency maximizing

In addition, the look compact of machine means it might be effortlessly incorporated into various production setups. The U Tech water bottling plant is versatile and therefore can create container different, including mini and large-sized water containers. It is well suited for tiny and water organizations that are medium-scale and it surely will assist companies optimize their earnings by increasing their manufacturing capability

The U Tech Complete water tiny Automatic Filling And Capping Pure Drinking Mineral Water Bottling Plant Machine Production Line is just a game-changing investment for companies that want to expand their water bottling systems. The gear quality and effectiveness are unrivaled available in the market, because of U Tech revolutionary technology and design. This water bottling plant is really a must-have for almost any company whoever objective is usually to offer safe and regularly ingesting top-quality is bottled with their clients. Get today yours have the great things about automation for the water company bottling

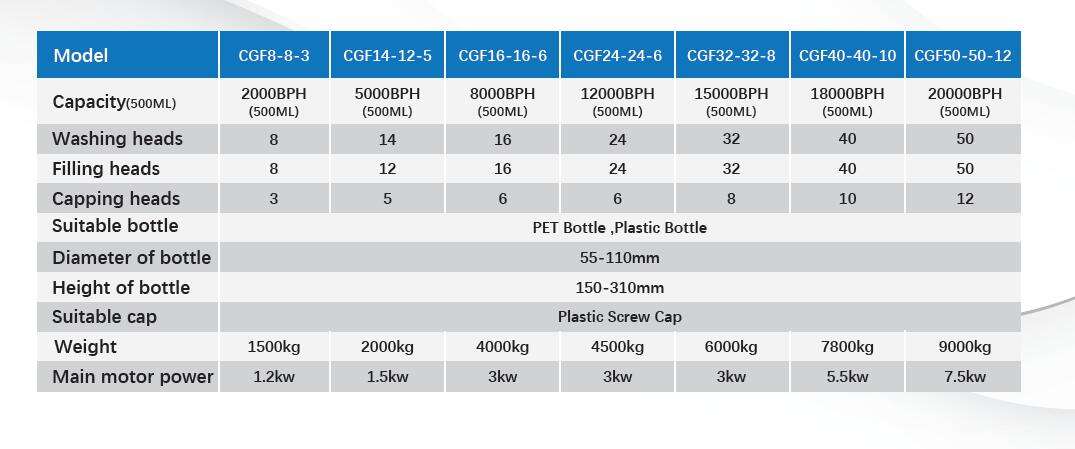

Model |

CGF14-12-5 |

Capacity |

5000BPH |

Washing heads |

14 |

Filling heads |

12 |

Capping heads |

5 |

suitable bottle |

PET bottle, plastic bottle |

Diameter of bottle |

55-110mm |

Height of bottle |

150-310mm |

Suitable cap |

Plastic screw cap |

Weight |

2000kg |

Main motor power |

1.5kw |

S/N |

Name |

Brand |

country |

1 |

Main motor |

ABB |

Switzerland |

2 |

Inverter |

MITSUBISHI |

Japan |

3 |

PLC |

OMRON |

Japan |

4 |

Touch screen |

MITSUBISHI |

Japan |

5 |

Contactor |

SCHNEIDER |

France |

6 |

Thermo- relay |

SCHNEIDER |

France |

7 |

Air-break switch |

SCHNEIDER |

France |

8 |

Proximity switch |

TURCK |

USA |

9 |

Photoelectric switch |

BANNER |

USA |

10 |

Air circuit system |

SMC |

Japan |

11 |

Water pump |

Southern |

China |

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer

Q2:What's your guarantee or the warranty of the quality if we buy your machines

>>A2:We offer you high quality machines with 2 years guarantee. we will give u spare part free in 2 years

Q3: Do you provide customized service

>> A3: We will customize the machine according to your needs, material power, filling type, the kinds of the bottles and so on

Q4:When can I get my machine after I paid

>> A4:We will deliver the machines on time as the date we agreed both side

Q5:How can I install my machine when it arrives

>> A5:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines