Material: 304 Stainless steel

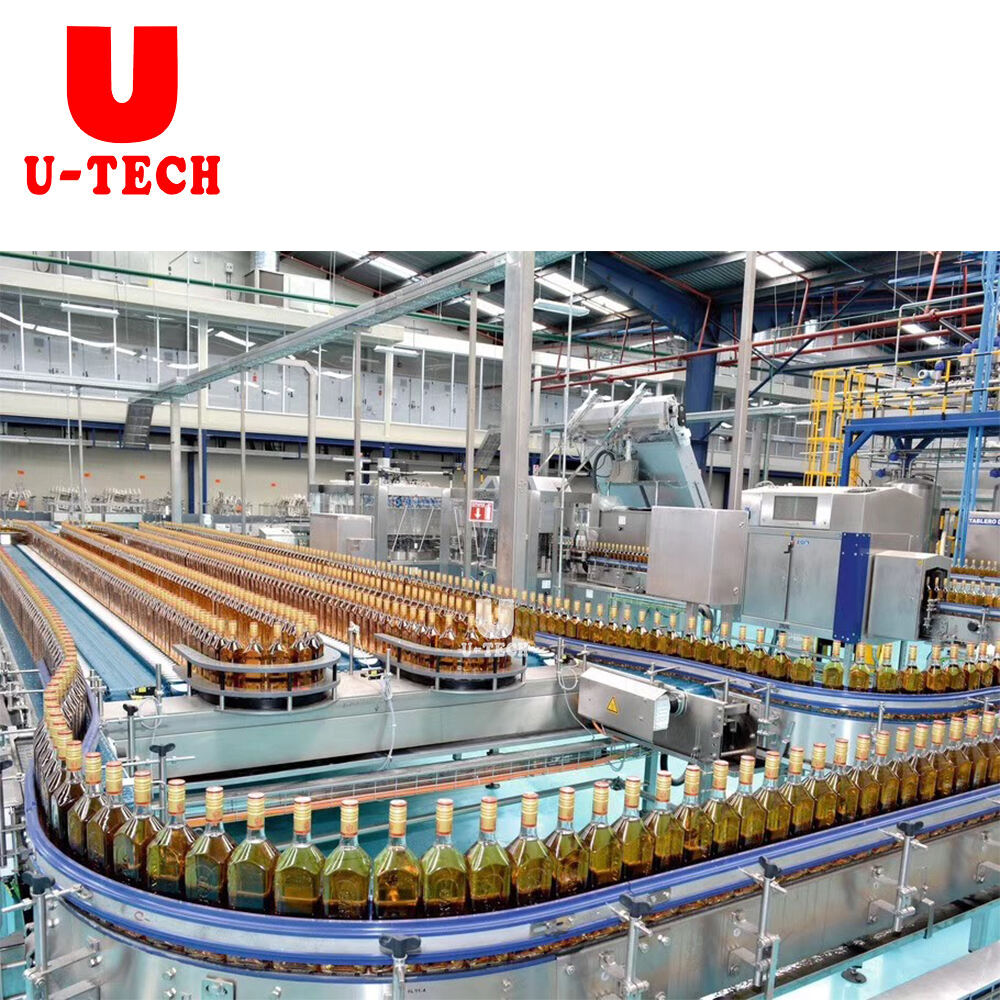

U Tech’s Cheaper Price A To Z automatic Glass Bottle liquid filling machine line vodka bottle Bottling Plant grape wine production line is an revolutionary solution for small to medium-sized organizations in the drink industry. This automatic filling was made to fill cup containers with liquids that make it ideal for creating top-notch vodka, grape wine, and other beverages.

This is fantastic for companies that want to streamline their manufacturing procedure without having to sacrifice quality. The product is simple to get results, making it available even for anyone that are not used to the drink industry.

This filling device is laden up with more impressive range technology that guarantees the precision and persistence of each and every fill. It features an automated container system, which eliminates the requirement for manual work, saves time, and increases effectiveness. These devices even offer an automatic capping that guarantees each container is correctly sealed.

U Tech’s Cheaper Price A To Z automatic Glass Bottle liquid filling machine line vodka bottle Bottling Plant grape wine production line was made from top-quality materials, ensuring durability. The outside components are made of metal, extremely resistant to corrosion. This feature made it easy to wash and maintain.

This filling machine has versatile applications which make it appropriate for different companies such as food and drink, chemical, and make-up. The product can fill containers of numerous sizes and shapes that make it an recommended alternative to many companies.

U Tech’s Cheaper Price A To Z automatic Glass Bottle liquid filling machine line vodka bottle Bottling Plant grape wine production line has easy instructions. Also, this system includes a warranty, giving clients reassurance on the performance and quality of the device.

Among the unparalleled features of this filling machine is its cost-effectiveness. It is cheaper compared to other brands available for sale despite having comparable features, which makes it a recommended item for small to medium-sized organizations. This is a fantastic investment to those seeking to increase their manufacturing level without investing way too much on equipment.

U Tech’s Cheaper Price A To Z automatic Glass Bottle liquid filling machine line vodka bottle Bottling Plant grape wine production line is a revolutionary solution built to streamline manufacturing, effectiveness, and profitability. This system is not hard to use, versatile, and economical, making it an unparalleled option for small to medium-sized companies in the drink industry. Invest in this system and boost your manufacturing level, profitability, and effectiveness

Model |

Washing |

Filling |

Capping |

Capacity(b/h)500ml |

Motor power |

Overall dimension mm |

|||

heads |

heads |

heads |

KW |

||||||

BFGF14-12-5 |

14 |

12 |

5 |

2000bph |

1.5KW |

2100x1400x2500 |

|||

BFGF18-18-6 |

18 |

18 |

5 |

3000bph |

2.2KW |

2460x1720x2650 |

|||

BFGF24-24-6 |

24 |

24 |

6 |

4000bph |

3KW |

3100x2100x2650 |

|||

BFGF32-32-10 |

32 |

32 |

10 |

6000bph |

4KW |

3500x2500x2650 |

|||

BFGF40-40-10 |

40 |

40 |

10 |

8000bph |

7.5KW |

4600x1800x2650 |

* All 304/316 stainless steel construction

* No bottle no capping

S/N |

Name |

Brand |

country |

1 |

Main motor |

ABB |

Switzerland |

2 |

Inverter |

MITSUBISHI |

Japan |

3 |

PLC |

OMRON |

Japan |

4 |

Touch screen |

MITSUBISHI |

Japan |

5 |

Contactor |

SCHNEIDER |

France |

6 |

Thermo- relay |

SCHNEIDER |

France |

7 |

Air-break switch |

SCHNEIDER |

France |

8 |

Proximity switch |

TURCK |

USA |

9 |

Photoelectric switch |

BANNER |

USA |

10 |

Air circuit system |

SMC |

Japan |

11 |

Water pump |

Southern |

China |

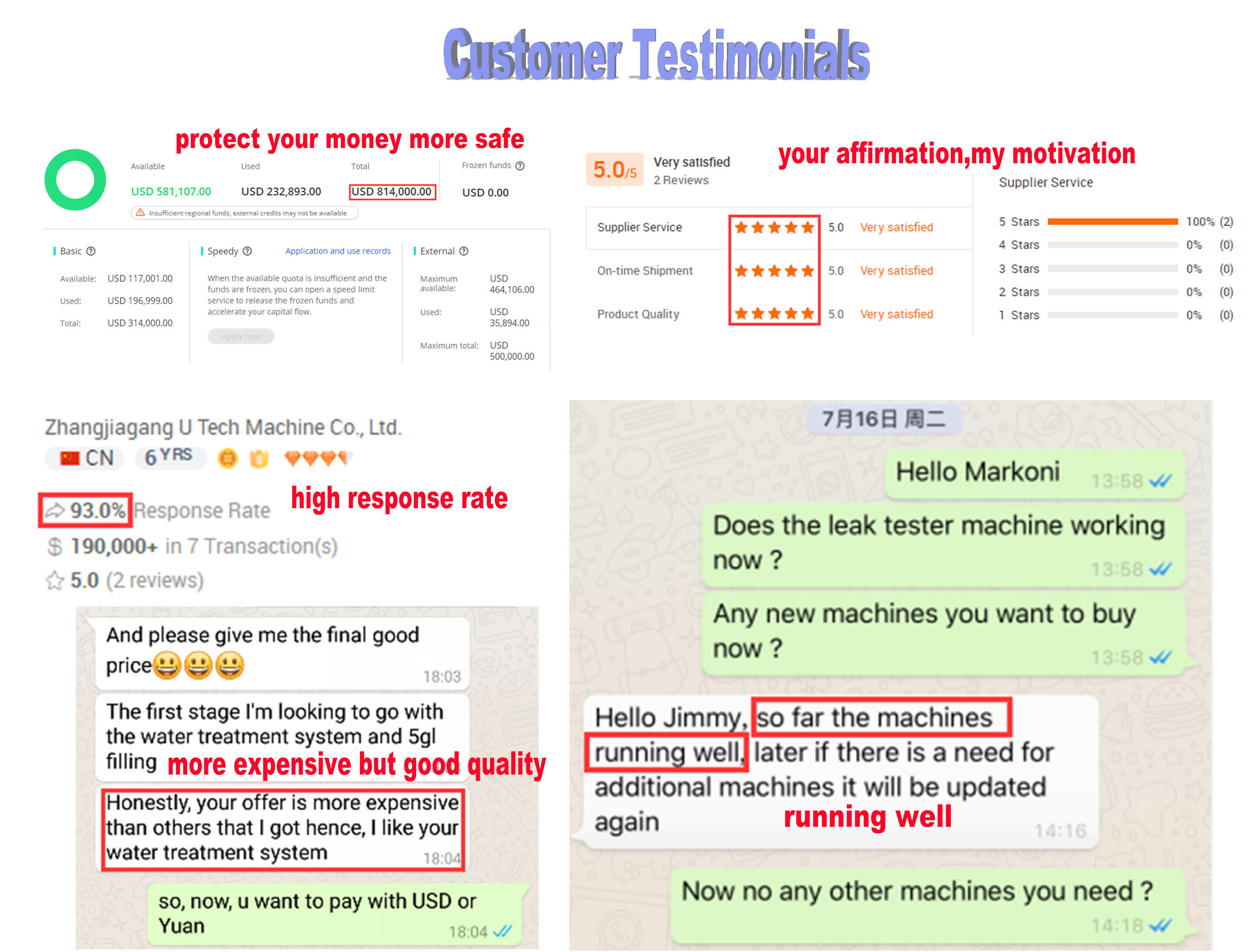

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee. we will give u spare part free in 2 years

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, material, power, filling type, the kinds of the bottles and so on

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines