The Automatic 300BPH Bottler device from U Tech is the perfect solution for filling and capping 5 gallon, 18.5 and 19 liters disposable bottles with purified mineral water. This machine is great for small and medium-sized companies to the water bottling industry with a manufacturing capability of 300 containers each hour.

The machine is sold with a computerized washing, filling and capping system. The washing system eliminates any debris and impurities in the containers, while the operational filling system ensures that constant and accurate amounts of mineral water are dispensed into each container. Finally, these capping devices and secures each container, making sure water keeps its purity and freshness.

Having a user-friendly design, this device is easy to get results and maintain. Every one of the major areas of the device was manufactured from top-quality stainless steel which is durable and resistant to rust, corrosion and wear and tear. Furthermore, the machine has automatic overload security features and security end buttons.

What sets the U Tech’s Automatic 300BPH Bottler Machine to its rivals is its use of higher level technology. The apparatus has a programmable logic controller (PLC) that controls the entire procedure of using the device. This makes it easier to create and monitor the bottler machine.

One of the fantastic features of U Tech’s Automatic 300BPH Bottler Machine is its flexibility. It can manage various sizes of containers, including 5 gallon, 18.5 liter and 19 liter containers. This makes it ideal for organizations looking to provide a number of sizes to their clients.

The U Tech’s Automatic 300BPH Bottler Machine is a superb investment for companies in the water bottling industry. This bottler machine will suit you perfectly and go beyond your expectations, featuring its automated washing, filling and capping system, high level technology, user-friendly design and flexibility. Choose U Tech for a dependable and efficient bottler machine, providing you with constant and top-notch outcomes

The whole filling speed ranges from 100BPH to 2000BPH

Filling the pure water or the mineral water in 3 or 5 gallons

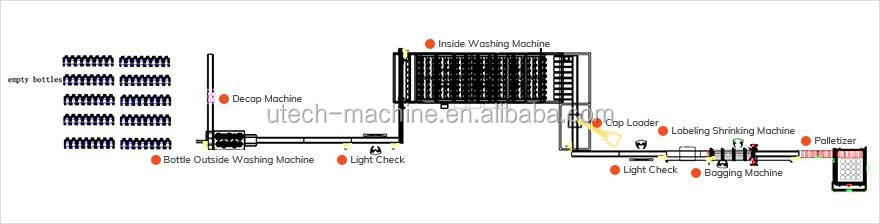

The series of machine integrate rinsing, contain rinser-filler-capper mono block, automatic loading machine, bottle outside washer, bottle inside washer, de-capper, heating shrink tunnel, conveyor system, complete line control system

Automatic barrel outer brushing machine specially work with 5 Gallon barreled water producing line. It is used for reducing the settling caused by the mineral water itself and some algae substances in the process of mineral water producing. The machine is made of excellent stainless steel with the advantage of easily-rinsing and corruption-resistance

1/Uploading and dropping barrels changed from 45 degree to translatory which is more stable.

2/Nozzle can insert into 10-15cm of the barrel in order to rinse little impurities down. Rinsing pump is separately controlled by different magnetic valves. Pump only work when there is barrel on that. It can avoid the mixture of different cleaning fluid

1/Liquid level difference is controlled in 1cm.

2/Machine is equipped with Cap Sterilization system, which is 1.2m. The system make products more clean and safe by using sterilization and finished water

1. The 5 Gallon Filling Machineis composed of barrel washer, barrel filling machine and barrel sealer into one unit.

2. Especially for filling drinking water of 3 and 5 gallons. It is an idea filling line to produce mineral water, distilled water and purified water

3. The whole line is made of superior stainless steel, anti-corrosive and easy to clean.

4. Only two operators are needed for a line, which is wholly automatic barreled

5. Full-auto or semi-auto barrel de-capper, full-auto leakage inspection, full-auto barrel outside brush, full-auto barrel loading machine, steam shrinking film machine and coding system can be choose depends on what customer's need

Model |

TXG-100 |

TXG-150 |

TXG-300 |

TXG-450 |

TXG-600 |

TXG-900 |

TXG-1200 |

TXG-1500 |

TXG-2000 |

||||||||

Working position, filling heads, capping heads |

3,1,1

|

5,1,1

|

7,2,1

|

9,3,1

|

11,4,1

|

13,8,1

|

15,10,1

|

17,12,1

|

21,15,1

|

||||||||

Capacity (5gallon)

|

100bph |

150bph |

300bph |

450bph |

600bph |

900bph |

1200bph |

1500bph |

2000 bph

|

||||||||

bottle specifications (mm) |

3gallon-5gallon

D=265-273mm H=150-360mm

|

||||||||||||||||

Main motor power(kw) |

1.41

|

1.5

|

6

|

30

|

32

|

35

|

40

|

45

|

52

|

||||||||

5 Gallon Water Production Line

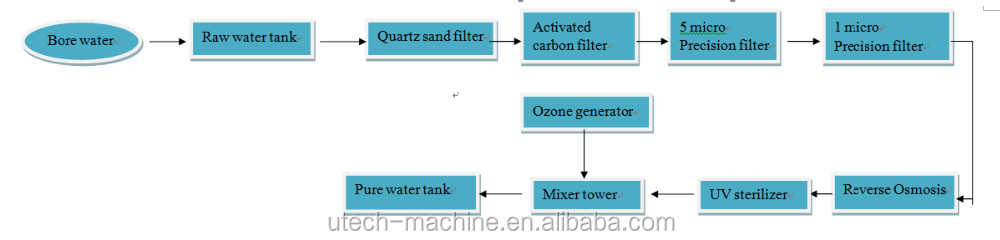

The company's Water Treatment System used in electronics, electro-plating, power plants, pharmaceutical, petroleum, chemical, food and beverage and printing industries to provide high quality water, reverse osmosis pure water technology is the most advanced, most economical, the most effective system of water technology, which is the use of ultra-thin film reverse osmosis membrane by water pressure, so that the water seepage from the high levels of salt to reverse the process of low salinity. Can remove most of the harmful substances, heavy metals, solids can be capacitive, only water molecules can only end through a reverse osmosis membrane water

Water Treatment Flow Chart

small water 20l 5 gallon bottle brush filling machine

small water 20l 5 gallon bottle brush filling machine

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts

Q1:Are you a trading company or a manufactory

A1:We are a manufactory, can give u best service

Q2:What's your guarantee or the warranty of the quality if we buy your machines

A2:We offer you high quality machines with 2 years guarantee. we will give u spare part free in 2 years

Q3:When can I get my machine after I paid

A3:We will deliver the machines on time as the date we agreed both side

Q4:How can I install my machine when it arrives

A4:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines

Q5:How about the spare parts

A5:After we deal down all the things, we will offer you a spare parts list for your reference