2. Special lubrication system, keep products clean, health, safety

U Tech

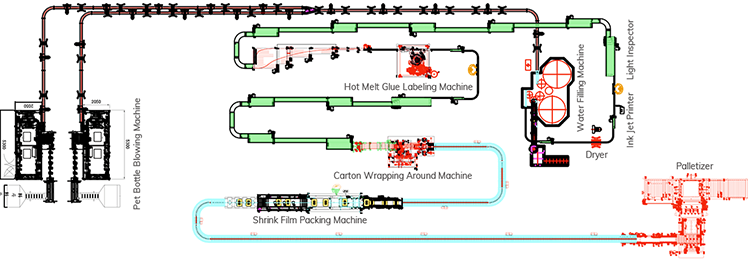

Presenting the U Tech 500ML Full Automatic 3 in1 table dining uncontaminated water filling capping device plant manufacturing line – a great item for organizations trying to increase their manufacturing effectiveness and streamline their operations

This device effective built to you need to take the job away from water bottling, filling and capping, doing all the work immediately. It steps in at 500ml and it is ideal for companies looking for a standard size container. These devices calls for minimal input from workers, freeing up more time for almost any other essential tasks featuring its automated abilities

The U Tech 500ML Full Automatic 3 in1 table dining uncontaminated water filling capping device is very user friendly, needing small to no training. Its perfect for companies that require to find a dependable and easy to utilize device which could ramp up manufacturing while ensuring persistence and quality. This product will work for little to medium-sized companies that want to get a fair, yet dependable solution to bottling, filling and water capping

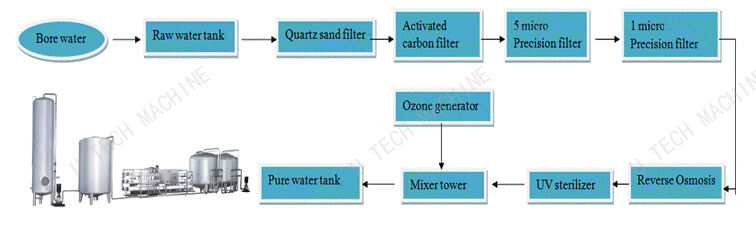

Perhaps one of the most amazing reasons for this device is its capacity to create mineral water pure. It really is an component essential numerous clients whom appreciate the health advantages of pure mineral water. With U Tech 500ML Full Automatic 3 in1 dining table pure mineral container water filling capping device plant manufacturing line, clients may be certain they are obtaining the standard water greatest feasible

The U Tech name brand is now similar to innovation and quality, this also item is any exclusion. It really is designed to meet with the greatest criteria available on the market which is guaranteed in full to final for many years to the future. No matter what the amount with every usage, companies is guaranteed they truly are finding a consistent and item reliable

The U Tech 500ML Full Automatic 3 in1 dining table pure mineral container water filling capping device plant manufacturing line could be the perfect solution for almost any company wanting to streamline their water bottling, filling, and procedure capping. You can easily take advantage of, affordable, and dependable, making this your choice perfect any ongoing company wanting to increase their manufacturing effectiveness. With all the U Tech brand name, companies could be guaranteed that they are finding a item top-notch was made to meet up utilizing the industry criteria which are greatest. Order your U Tech 500ML Full Automatic 3 in1 table dining mineral container water filling capping device plant manufacturing line today and just bring your organization to your degree next

Model |

CGF8-8-3 |

CGF14-12-5 |

CGF16-16-6 |

CGF24-24-6 |

CGF32-32-8 |

CGF40-40-10 |

|||||

Capacity |

2000PBH 500ML |

5000PBH 500ML |

8000PBH 500ML |

12000PBH 500ML |

15000PBH 500ML |

18000PBH 500ML |

|||||

Washing heads |

8 |

14 |

16 |

24 |

32 |

40 |

|||||

Filling heads |

8 |

12 |

16 |

24 |

32 |

40 |

|||||

Capping heads |

3 |

5 |

6 |

6 |

8 |

10 |

|||||

suitable bottle |

PET bottle, plastic bottle |

||||||||||

Diameter of bottle |

55-110mm |

||||||||||

Height of bottle |

150-310mm |

||||||||||

Suitable cap |

Plastic screw cap |

||||||||||

Weight |

1500kg |

2000kg |

4000kg |

4500kg |

6000kg |

7800kg |

|||||

Main motor power |

1.2kw |

1.5kw |

3kw |

3kw |

3kw |

5.5kw |

|||||

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer

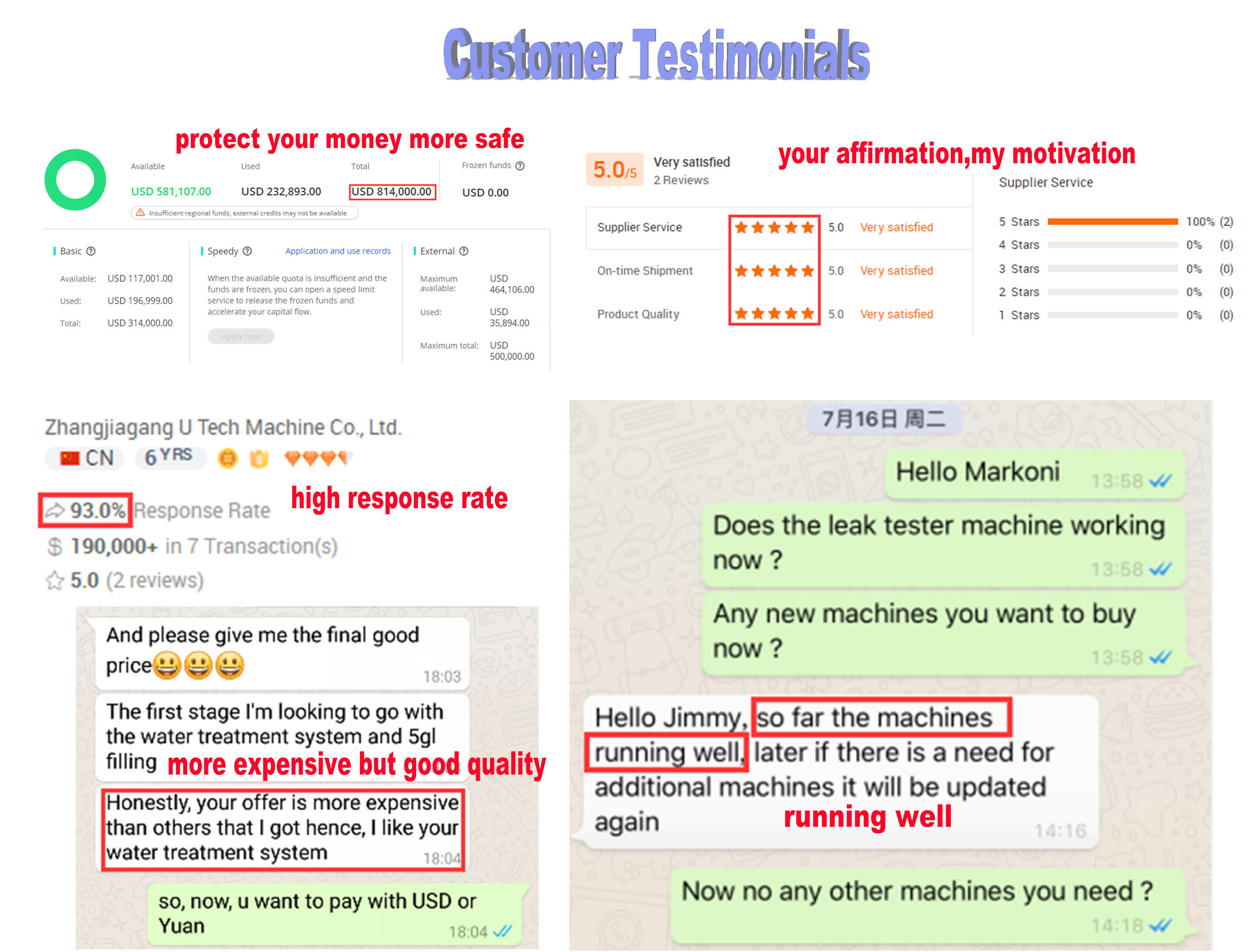

Q2:What's your guarantee or the warranty of the quality if we buy your machines

>>A2:We offer you high quality machines with 2 years guarantee. we will give u spare part free in 2 years

Q3: Do you provide customized service

>> A3: We will customize the machine according to your needs, material, power, filling type the kinds of the bottles and so on

Q4:When can I get my machine after I paid

>> A4:We will deliver the machines on time as the date we agreed both side

Q5:How can I install my machine when it arrives

>> A5:We will send our engineer to your side as soon as you get all your machines ready for testing and teaching your technicians how to run the machines