Product introduction

Is fully mechanical with variable speed drive and gravity/counter pressure filling system. The whole equipment is sleek and is capable of bottling various sizes of bottles ranging from 500 ml to 2 litres. The mineral water bottles are fed into the rotary rinser, filler, capper by means of an input feed conveyor. A star wheel then transfers the bottle to the neck holding robot of the rinsing station. Bottles after being rinsed are automatically transferred by a star wheel to the filling station. In the filling station the bottles are picked up by the neck and are allocated individual filling valves. The state of art filling valve is so precise and accurate it gives even filling in all bottles.

Technical parameter

| Model | CGF16-16-6 |

| Capacity | 8000PBH |

| Washing heads | 16 |

| Filling heads | 16 |

| Capping heads | 6 |

| suitable bottle | PET bottle,plastic bottle |

| Diameter of bottle | 55-110mm |

| Height of bottle | 150-310mm |

| Suitable cap | Plastic screw cap |

| Weight | 4000kg |

| Main motor power | 3kw |

Machine details

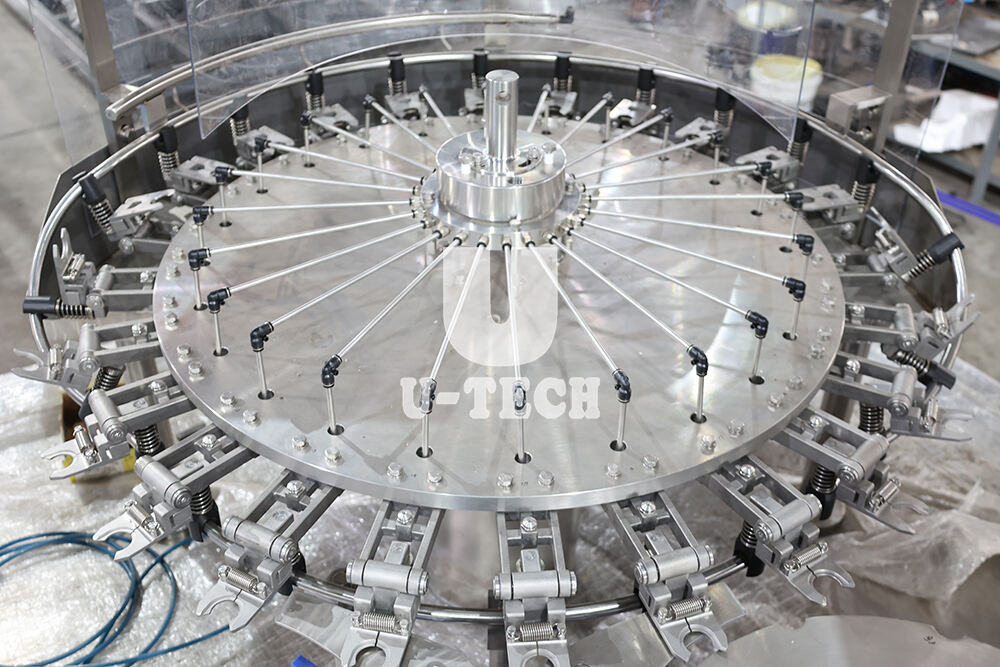

Washing part

The stainless steel grasp will hold the plastic bottle neck and turn 90 degree. There are two steps in this part, one for washing and one for dripping before entering to filling station.

Filling part

Adopt gravity filling method. There is an air return pipe inside the filling valve to control the filling level; Such filling method is the easiest way of filling machine.

Cappingpart

Introduce most advanced cap sealing technology called France “ZALKIN ". With the help of expert from institute of electro mechanics and mechanical engineering of Shanghai Communications University, we successfully designed.