Product introduction

Bottle drinking water production line . CGF 3 in 1 unit combines rinsing , filling , capping complete automatic line .Machine is suitable for non-carbonated drinks pure water and mineral water .The whole process is set up with alarm device in case the bottle jammed , lacking missing and over loading . With complete system highly automatic .It meets the food hygiene standards with capacityis 2000BPH.

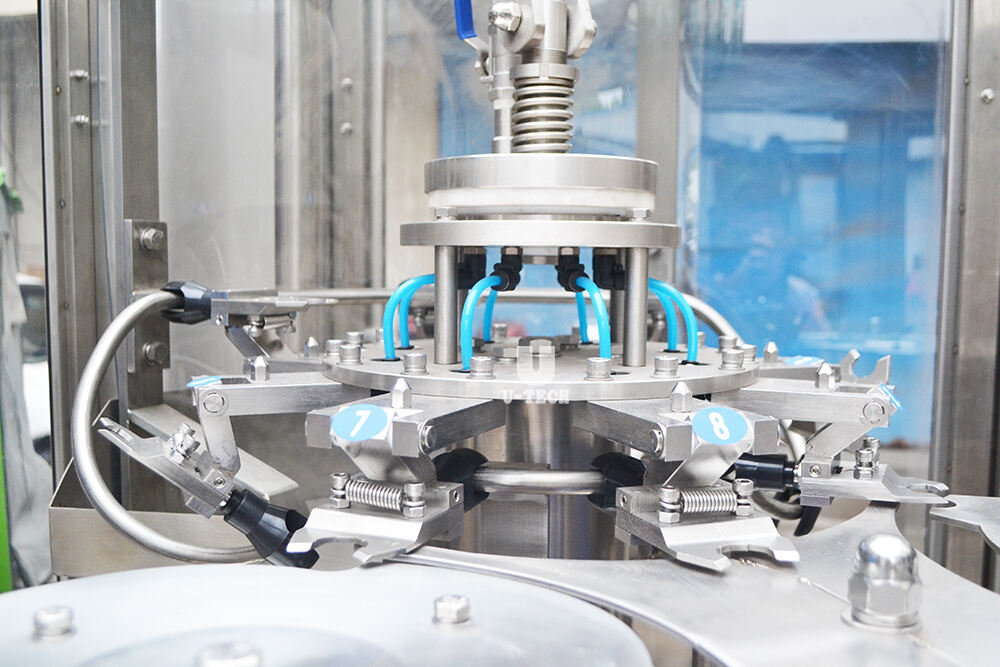

Machine details

Washing heads

Into bottle way is air conveyor direct connection with bottle dial.

1.All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

2.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

3.304/316 stainless steel washing pump make the machine more durable.

Fillingheads

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. Efficient spray nozzle rinse thoroughly and save water for flushing

Cappingheads

1.Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2.All 304/316 stainless steel construction

3.No bottle no capping

4.Automatic stop when lack of bottle

5.Capping effect is stable and reliable, Defective rate≤0.2%

Technical parameter

| Model | CGF8-8-3 |

| Capacity | 2000PBH |

| Washing heads | 8 |

| Filling heads | 8 |

| Capping heads | 3 |

| suitable bottle | PET bottle,plastic bottle |

| Diameter of bottle | 55-110mm |

| Height of bottle | 150-310mm |

| Suitable cap | Plastic screw cap |

| Weight | 1500kg |

| Main motor power | 1.2kw |