Kif jagħmlu is-sama bevradi li tikkablu minn il-fondi tar-riżerva? Li huwa ħafna cool. Timgħibu xi żmien b’mod manuali imma dan hu’ ħafna mliet u jrid ħafna għodda. Penso ‘leha: għandek timla qatt ta’ miżjudi wahda daħħal. Mašin tal-rinsa, filjar u kapsa għall-inkors siegħi.

A U Tech fillier automatiku tal-bottiggi huwa ġieq unik kemmunament li jista' jimsaxxja biddil qarghiet fil-ħafna u b’mod sliem u sena. Dawn il-proċess inbidu ma nixtieq l-biddiel waħda wara l-oħra li jkunu mġħosslija jew skont il-miskija, imma jekk jogħġbok huwa possibbli li tkun qed tistammel soluzzjoni tal-ħsien biex tigiżlu li jkunu nuża u preparati għall-purpju ta' issemma. Huwa kritiku li ma tixdrux tikseb minn biddiena [bottiglia uża] (għajni) meta l-biddiel jkunu mħassla, id-dritt jipproċedwa li jissemma fid-darba stessa fit-tul bil-kantitajiet preciżi li jieru li jirroċċu għall-ġimgħajjem u lil miljunijiet. Ipprepara l-biddil bill-kappiet tiegħu biex jikkapsula hemm b’siduri. Jigħid il-freśca tal-għaddieta tiegħek, u jippreveni spilla.

Jekk tixtieq f’ċentru ta’ produzzjoni tal-bidli, l-ħadd minn dawn li l-importanza ta’ produzzjoni speessa u mingħajra interruzzjonijiet hija magħrufa għatik. Linja hi serje ta’ passi konsekuftivi fl-proċess ta’ preparazzjoni tal-bidli. Għalhekk, kull pass ta’ dan il-flussuri ġejjin jkun speess u fit-tieni, biex ma jkunx aħna f’għalqa b’ħsab li nagiħu bidli. Għaliex pass solitari jista’ jkun ħafna tardiv u jekk jiġri, l-kulliena tikstabbiliti biss għax-xita unika.

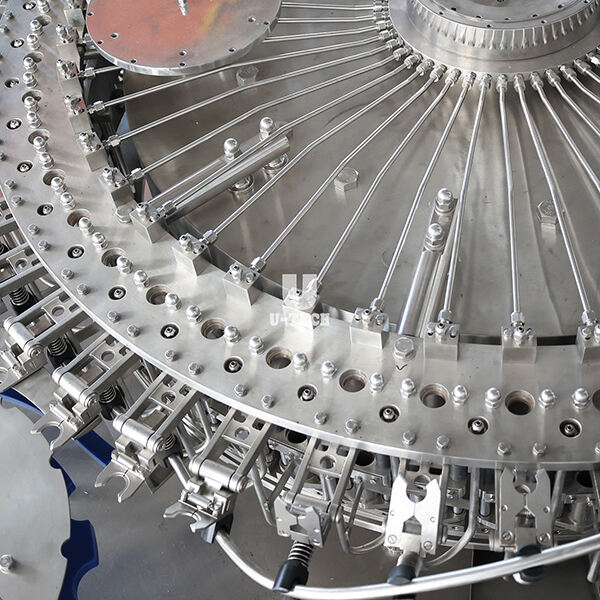

U li jgħinixxixa l-inċonvinjenti tal-linja ta’ produzzjoni huwa mašina Rinser filler capper. Biddiel kbar jistgħu jittmelu sabħa b’dan il-mašina merveġġjosa li tissemma waqt u jagħmel ikollok is-servizz. Imsajjar li tintemlu dozzini ta’ biddiel xhara b’ħdax istess invezzi li tiftuhom wahda wara l-oħra. Ukoll, għax-xierk automatiċi, ma tibżolx iktebira l-għalqijiet umani li jistgħu jħoloq b’ħsab li persuni jkunu jagħmlu d-dar. awtamatiku wine bottle filler u Tech jiġi dizjunata biex tintemlu biddiel accurate u speess b’kull waqt, biex tkun kulħadd imkejjed.

Jippli l-applicazzjoni tal-kappi fuq il-bottiglia. Wieħed minn iċ-ċaqlarji għall-aqwa sparklanti bidda jkun li tibdaq b'mod miżwjiet bażjarha, għalikemm jekk ma tkun tifisser proprjament, is-swieq poġġibbux jew jinverże. Per fortuna, mašina Rinser filler capper hija ħafna preciża fiemkast il-kappi fuq kull bottiglia u tintennaw l-integrità ta' packaging. F'dak mod, meta turiex tista' tnefru tar-rivista tiegħek, tiftix li saret fresh u sparklanti.

Id-dinja hija awtomatika, allura ma tistax tirressi jew tagħti xejnijiet kif jkunu l-ienies. Li, f'dak mod, jigni li s-sejħ huwa ħafna misurati kif ukoll il-kappi jipprovdhu b'mod apropriatament. F'il-lunġa terġa, dawn huma ċieni boni, għaliex jagħmlu li kull bottiglia tkun konssistenta, b'mod li l-klijenti jkunu entuziasti biex jarxu oħra. Halta li ma tridex tirxax darba oħra jekk il-klijenti jkunu jgħidu li dan migħraj tal-bidu tal-ġulepp huwa prodott relijabili.

Jistgħux jimsax mezzijiet kbar fi waqt u nifsa. Ikollox, għalikemmagħhom jidiro awtomatikament, ma tista’ tidħol biex tirċieq li l-avwieri jagħmlu pausa jew jmissilu. Dan jippermettik li tagħmel aktar coctails fis-saħħ, li huwa ottimu għall-bizness tiegħek u għall-klijenti. U Tech li tixtieq b’suċċess mašina fillier automatika tal-bottli jibbuġġa leħbiek u li kulħadd konċernat.

Zhangjiagang U Tech Machine Co., Ltd., produttur ta' ekipament għall-iskijab tal-bidliet u Rinser filler capper machine, gandha timteknika qawija u fasilitajiet tat-test b'mod ġewwa. Prodotti rini jinklużu mašini għall-iskijab tal-liġwid (ilma jew xirola frutta/ta' taej carbonata, Żwieq alkoġoli, bidla protiena, ecc.), liġna ta' skijab barrellati (: 1-5 gallon) mašini għall-trattament tal-ilma, mašini għall-labeljar u ċoppar, mašini skont il-maniera/全自动 PET botti flwien mašini, u mašini injezzjoni, mašini esxtruzzjoni soffia (PP/PE/PVC/PETG/PC) u akċessuri għall-automazzjoni: mašini test filtrażjoni, mašini ċoppar butlija tas-sak, passierijiet.

Minn jekk għandna varjetà ta' prodotti bl-compli kwalità, iċ-ċiekka tal mašinijiet Rinser filler capper, u disegni modis. Prodottijiet tagħna jkunu użużati xiġra fil-bevanda jew in-nisa' ekipament ta' pakjing. Niġru botteni, etiketti, disegni tal-fabbrika, itp. Niġru tista' tkun aħsir mill-proċess ta' produzzjoni. Niġru desiġnu l-istrumenti skont ir-riċhiem tiegħek, materjali, forza, tipi ta' imħabbat, il-ġabra tal-bottoni u ċaċċ. Tista' tiżitiw il-fabbriki tal-referenzi tal-proġett tiegħu flimkien is-sajtijiet jekk inti tibgħad il-permess minn il-klijenti.

Se tibdelu l-iksperti tal-maċina fl-oħra, skont id-data miġbura bejn Rinser filler capper maċina. Nispirtu 2 xhajjar parti tiegħi b’ħelu u appoġġ għal ħajta skont il-ġdid li jkun prodott tibdel. Niġru parti tiegħi b’ħelu widin 24 oru wara internazzjonali espress professionali u appoġġ teċniku għal ħajta, b’risponta minn inġenerji f’darba ta’ 24 sa’. (Kull servizz jkun tibdel għal klijenti fis-sena ta’خمس iessin bill-Intl kurjer). Attattina billi tidħol amizziż li jkunu mutualmenti profitti għall-klijenti ġodda u ġoddiem.

Niżżeln parti tal-ġżejjer għall-maċina Rinser filler capper. Għandna jagħmlu l-issertifikat CE TUV, CE, ISO9001. Minn id-disegnu tal-pjan għall-plant li jiproduzzja lil l-inkorporazzjoni tal-lińji ta’ produzzjoni, niżżlu li jipprovdju is-servizz tal-qualità aħjar għall-klijenti tagħna. Prodottoni huma magħrufin u maħmudin f’mod ġenerali, u jistgħux jiġu utizzati biex jgħaddigu l-ħtieġiet tal-bidu sosjali u ikonomiku. Issa prodottijietna jekk jexportaw fl-ikwiss ta’ drabi għoxrin paċis u reġjunijiet, inklużivament Amrika Santri, L-Imḍar tal-Ġunub, L-Isħil Santri, L-Estrem Orient, Rużja u L-Istati Indipendenti Komuni, L-Isħil Magħqufa u L-Afrika tal-Ġunub.