Do you want to escape the boring job of filling one water bottle at a time? Doing this manual labour for hours can be tiring and time taking task. Here is where the use of the state-of-the-art automatic bottled water filler can innovate your manufacturing line.

Eliminate manual water bottle filling by adaptive the use of a mechanical canteen in-filling mechanism to make it up for inefficiency. You can fill several bottles at the same time using this latest technology, so you save a lot of effort and reduce labor costs in terms of manpower. By letting the machine handle all of your filling, you can free up space and time for you and your team to focus on more important parts of running a business.

Can you picture the perfect water bottle fill-up process that work every time as long and never loses efficiency? Practically, a water bottle solution itself - where it can help to make your production line move forward and also introduce about those advanced slippers requirements. This system saves the time, energy and cost for manually filling bottles of waters automating this process in an excellent long-term investment.

Say goodbye to inconsistent results caused by manual bottle filling. The use of an automatic water bottle filler as in the case above guarantees that each and every single bottle is filled with precisely the right amount to do this, meaning consistency across all batches. Not only does this improve your product quality, it also reduces waste and increases the overall efficiency of your operation!

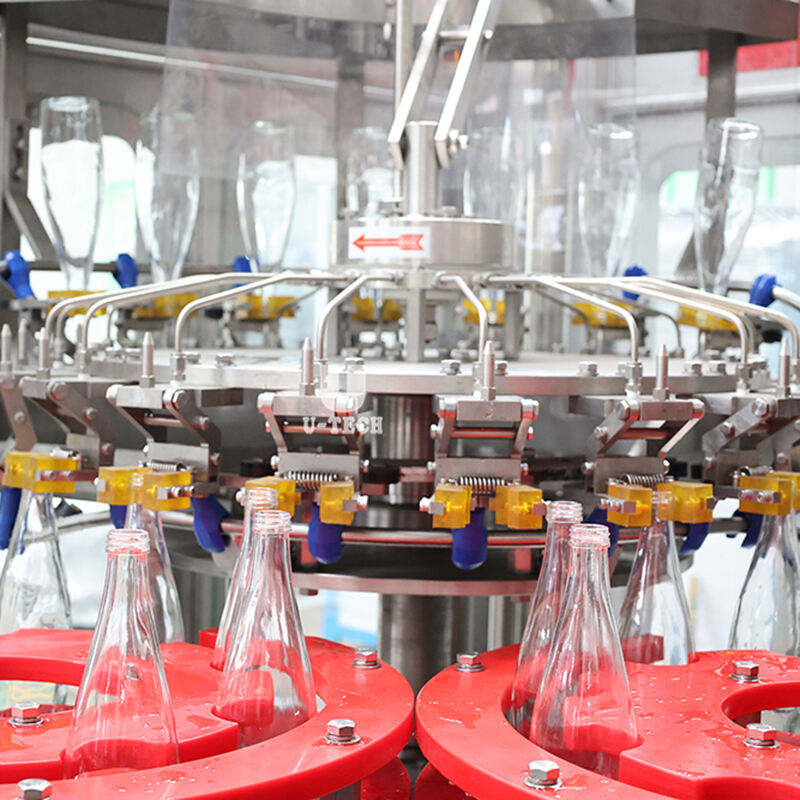

Do you want to turn your brewery or beverage plant into an innovation center? Think about including a modern bottle filling machine to your assembly line. This packaging solution is particularly effective for streamlined operations, allowing bottles to be filled, capped and labeled in one automated process using state-of-the-art equipment.

This machine is built to handle the workload of thousands bottles, perfect for high-demand operations. This automation provides you with more time to focus on those high impact business decisions that really drive growth and success.

Is your production line hurting from an inability to keep up with growing orders requirements? You may find that a high-speed water bottle filler is the answer for you. This equipment not only reduces downtime but boosts productivity through increased filling rates, meaning a more streamlined operational flow.